(Or "Whomever is selling drugs to the engineers at Edelbrock, please stop!")

Since I had removed and reinstalled my original intake manifold several times (and thus torqued the intake bolts several times), I decided to purchase new intake manifold bolts. Like a moron, I assumed that OEM bolts would simply work on the new Edelbrock manifold exactly as they had on the old, OEM manifold. Little did I know that the nice engineers at Edelbrock had forgotten to consider bolt head size when designing the plenum portion of the manifold (or were too lazy to care). The result? It is impossible to use the "correct" bolts to install an Edelbrock manifold onto a Ford engine block. This does NOT instill confidence in the Edelbrock company. (see below)

Of course the first thing I tried was a socket-head-cap-screw. That didn't work, either. The only option I could see was to use a stud. However this stud would have to be made to my exact specifications. The only way to accomplish this task was to manufacture a prototype and hope the local fastener store had 3 more matching studs. How wrong I was. Long story made short, I had to manufacture all 4 studs myself.

Though the stud idea works, it's a very tedious and non-scientific process to install them. I can't believe an entire panel of Edelbrock engineers deemed this mounting method acceptable. One has to work the stud from the top and bottom in order to get it installed. Any slight resistance to screwing in the stud (and there's always resistance) facilitates the need to use needle-nose pliers to work the stud into the block. This causes the risk of inducing metal flakes into one's engine. One has to be extremely careful when doing this. This process is a real pain in the ass with the engine sitting on a stand. This work would be a total PITA if it had to be done within the confines of the engine compartment. Shame on you, Edelbrock. Bad engineers! No doughnut!!

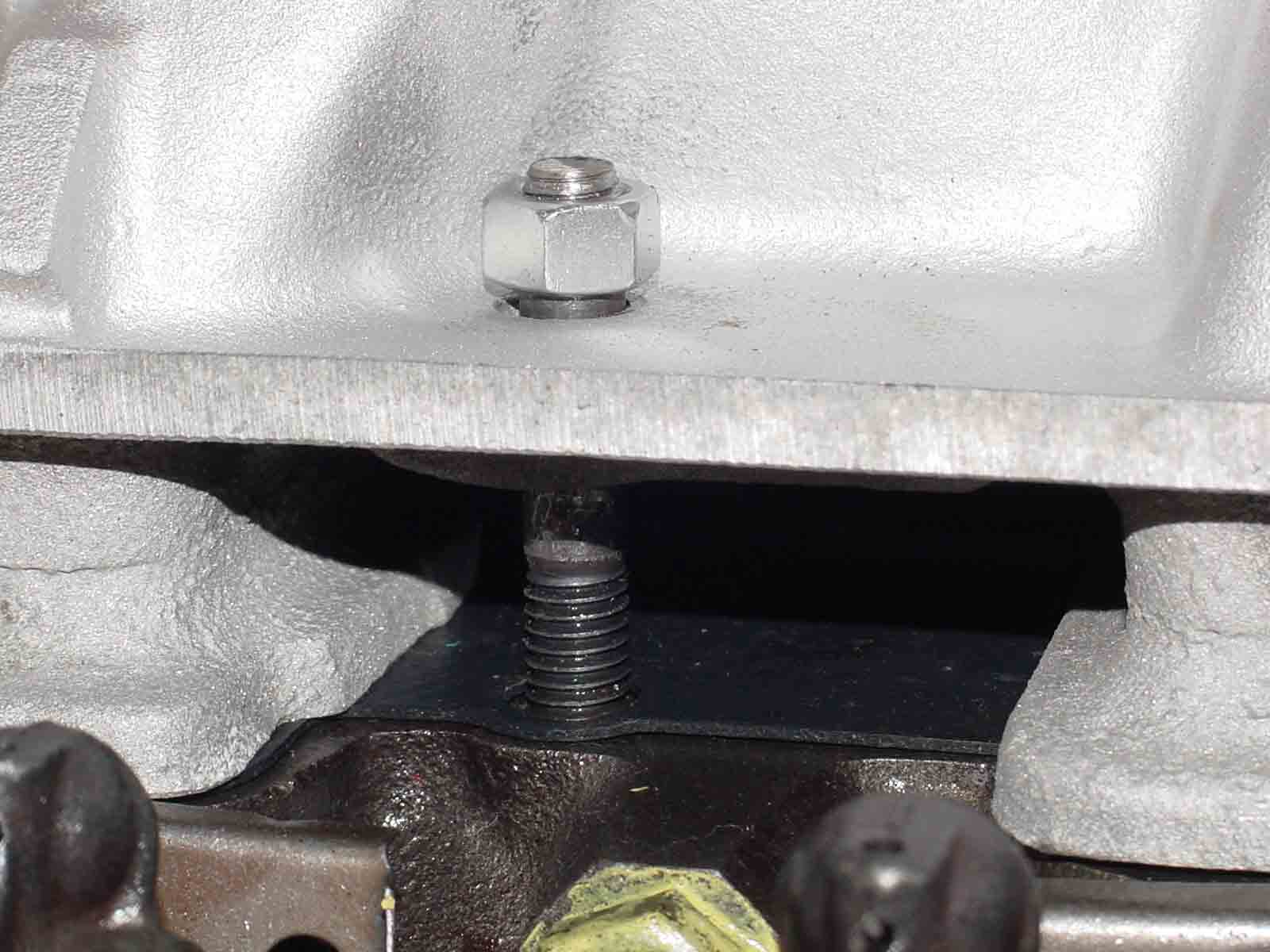

Once the stud had been tested for fitment, I then tapped the new stud and put a nut on it. I purposely used the same size thread on both sides of the stud so's not to mess with my torque specifications, which was going to have to be done by "feel." As you can see, my new studs work perfectly. God willing I will never, ever, ever have to remove this manifold. What the hell were the Edelbrock engineers thinking with this???

This page is up as of May 31, 2005 - 1:10 AM and updated July 27th, 2005 - 4:55 AM.

Comments? Corrections? Questions? Please

e'mail me to tell me about it.